Joining and assembly

Unimed performs a variety of techniques and can propose appropriate methods of joining single and multiple parts in order to meet any specific requirement. In some cases we may propose more than one type of joining, at different price levels.

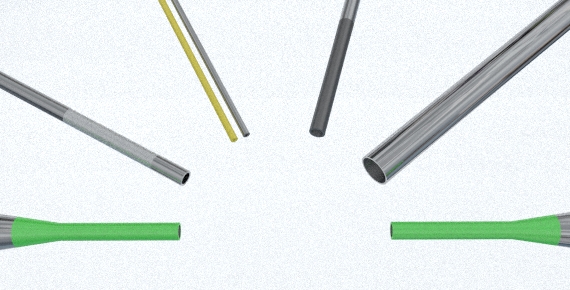

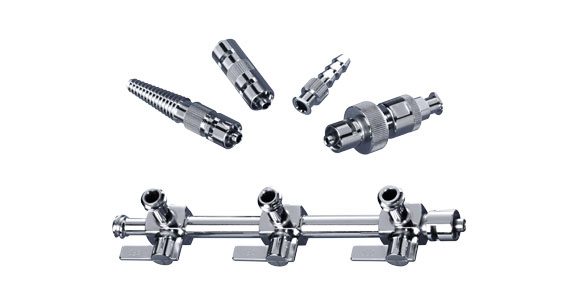

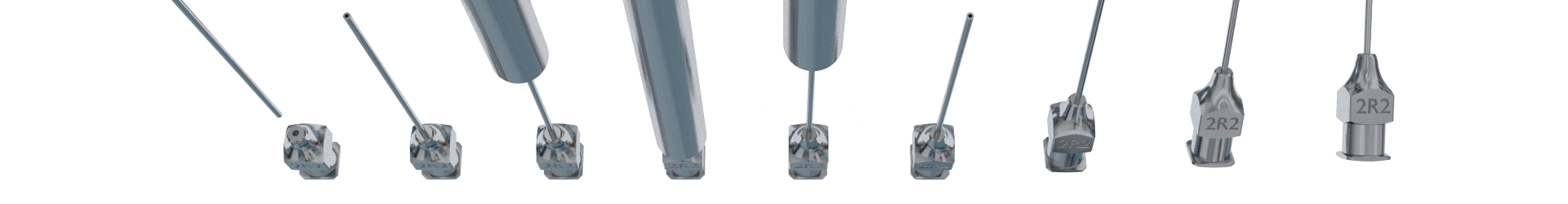

- Press-fit or Crimping/Swaging. These are proven low cost methods of joining tubular parts in repeatable quality.

- Epoxy Adhesives offer economical and reliable assemblies for a number of applications. Different kinds of adhesives are available to meet customer requirements in terms of temperature, chemical resistance, food and medical compatibility (USP class VI) or sterilization for multiple use.

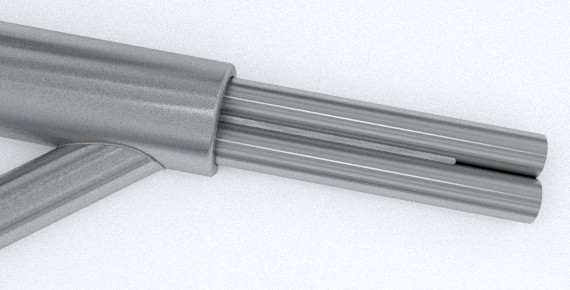

- Laser Welding is ideal for small thin-walled components, offering the advantage of minimal heat effect in the weld zone. This process allows to weld in special circumstances where a high energy density is required.

- Brazing is often used for joining dissimilar material combinations, thin sections to thick sections as well as inaccessable joint areas which are unweldable. A distinction is made between low-temperature soft soldering (tin alloys, approx. 200°C) and high-temperature hard soldering (silver alloys, approx. 700°C).

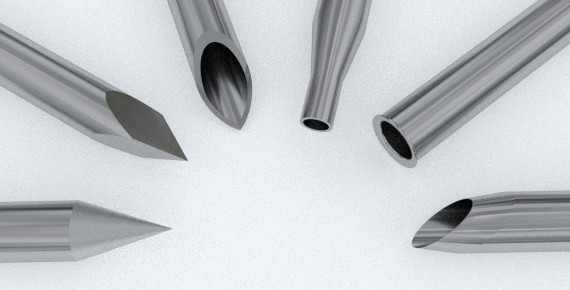

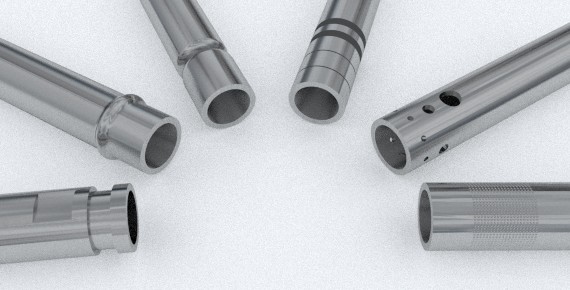

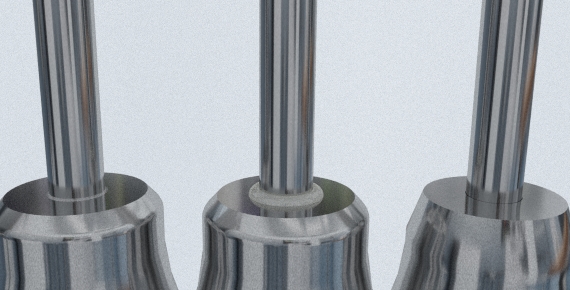

Here are some examples :

Epoxy adhesive assembly

Laser welding assembly